“Wire drawing” is when the valve seat wears out at one area from operating with significant pressure differential near but not completely closed. This can be caused by not closing the valve all the way, such as using a control valve as a makeshift hand expansion valve, but it’s usually caused when debris is caught on the seat. Once the valve seat is compromised this way the wire drawing will continue to get worse due to erosion. Let me show you one such valve that was recently taken out of service:

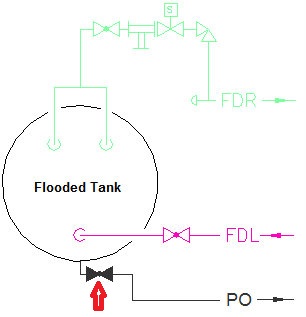

You can see that in this case there was a decent sized piece of welding slag that got caught on the seat. This is from a hand valve between a pump-out line (16” of suction) and a flooded liquid line operating at 45psig. Here’s a simple schematic showing you the location of the valve: