IIAR Bulletin 110, Section 6.4.4 calls for something called an “Independent Full Inspection”:

At least every five years, the annual inspection of the vessels and heat exchangers shall be carried out by a competent person independent of immediate commercial and production pressures for that installation, who shall carry out whatever examinations and tests he may consider necessary in order to determine that the equipment is safe for further use or in order to specify such repairs that may be necessary. Special attention should be paid to possible deterioration of areas around supports, particularly of horizontal vessels and the attachments to the vessels. Any inspection of heat exchangers should include tubes and tube-plates whether or not the refrigerant passes through the tubes.

Although it is recognized that the method and extent of testing will be determined by the competent person, who will take into account any relevant regulations, standards and codes applicable at the time of the inspection, guidance is given below on the typical extent of testing envisaged in the preparation of this Bulletin.

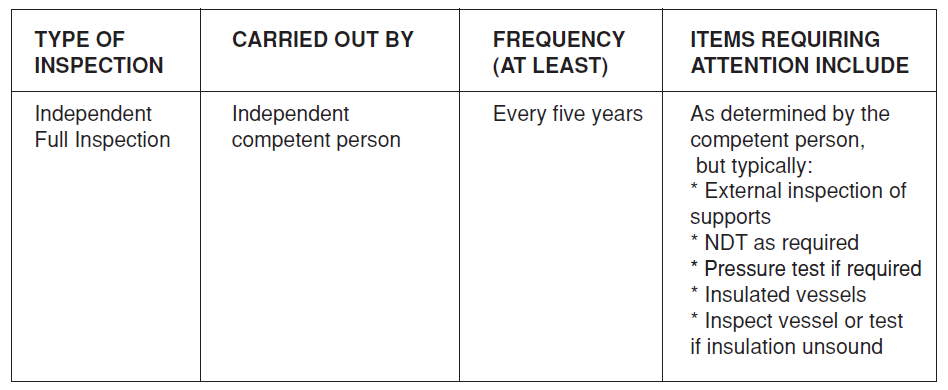

Appendix G offers a summation of the requirements:

Unfortunately what we are seeing in the field is a bunch of Bulletin 109 forms being filled out with no documented inspection of supports, insulation or Non-Destructive testing.

This is leading to quite a few fines and it’s something that could easily be stopped if the people requesting the 5 year inspections from their contractors (or the contractors themselves) sat down and read the requirements of the bulletin.

It’s very important we understand WHY this inspection is so vital: The ammonia refrigeration industry does not want to have the API (American Petroleum Institute) standards thrust upon us. In an API system every valve, run of pipe, vessel, etc. is tracked and you know quickly it is corroding, how long it will last, when to replace it, etc. In the system most ammonia refrigeration plants use, we have no such tracking. Yes, we do normal preventative maintenance and inspections, but we don’t have a good answer to the question: How long will that pipe/tank/equipment last? The 5 year independent full inspection is meant to answer that, in part, by saying : At least another five years.

An independent full inspection is meant to do things we don’t normally have the expertise to do: Figure out if the supports are still able to hold the loads, quantitatively measure the corrosion in pipe, etc. Your own people can fill out Bulletin 109 forms if you find any value in them, the independent audit is about having experts do the things you can’t or shouldn’t do in house; It’s about having a fresh set of eyes on your system.

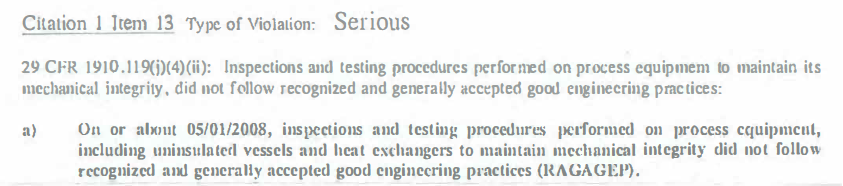

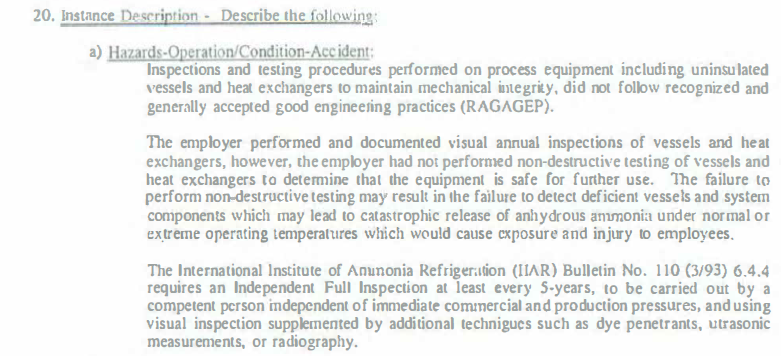

Failing to do this will usually result in a 1910.119(j)(4)(ii) citation:

Update 7/11/2013

Please note: You also need to do annual checks but these can be done in-house.

Section 6.7.1 of the IIAR Bulletin 110, Guidelines for Start-up , Inspection and Maintenance of Ammonia Mechanical Refrigeration Systems, states : “All uninsulated piping and associated components such as flanges and supports shall be inspected annually for any damage to or deterioration of the piping or its protective finish; take remedial action where necessary . Section 6.7.2 states: At least as part of the annual piping inspection, but preferably more frequently , the external condition of the insulation and supports shall be inspected.