Recently a group of safety yahoos got together to discuss a situation:

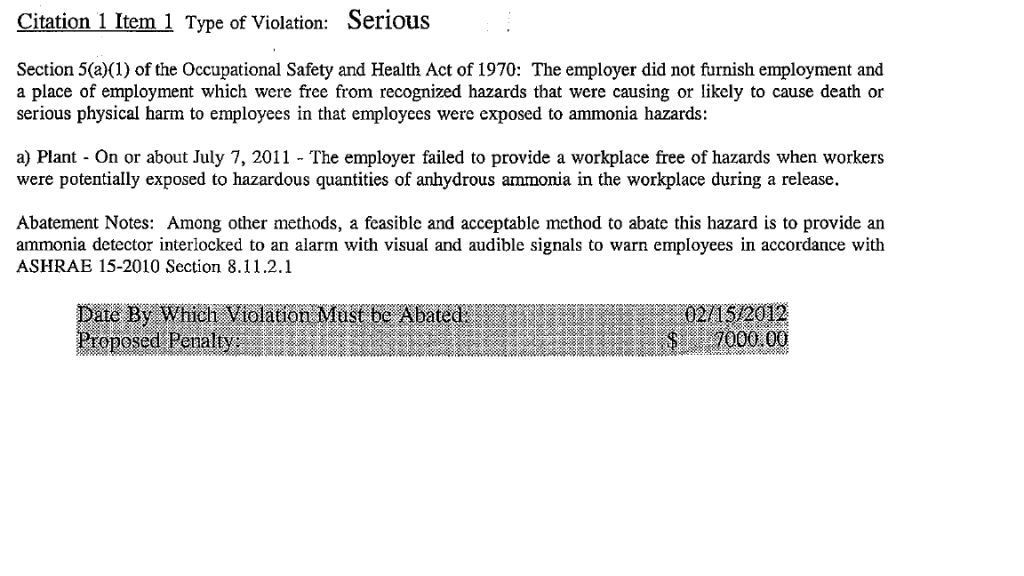

You have a freezer with racking. The racking needs to be removed for XXXX reason. You hire a contractor to do the job. You evaluate and train the contractor as a PSM Contractor. In the midst of removing the racking, the contractor strikes some NH3 piping with a forklift and cause a NH3 release. NOTE: the piping in this scenario is 18″ above the rack and against the wall and ceiling, but not protected in anyway and the driver of the forklift was trained for the forklift he was operating. The racks were used to store products that were handled by hand – not by forklift, so the forklift being used to remove the racks is only in the freezer to install and remove racking.

One of us posted this to the LinkedIn forums and promised each other not to comment on it until the conversation ran it’s course. There seems to be two camps: the Non-MOC camp is best represented by Bryan Haywood of SAFTENG.net. What follows is my response to that camp:

“The major objective of process safety management of highly hazardous chemicals is to prevent unwanted releases of hazardous chemicals especially into locations which could expose employees and others to serious hazards. An effective process safety management program requires a systematic approach to evaluating the whole process. Using this approach the process design, process technology, operational and maintenance activities and procedures, nonroutine activities and procedures, emergency preparedness plans and procedures, training programs, and other elements which impact the process are all considered in the evaluation. The various lines of defense that have been incorporated into the design and operation of the process to prevent or mitigate the release of hazardous chemicals need to be evaluated and strengthened to assure their effectiveness at each level. Process safety management is the proactive identification, evaluation and mitigation or prevention of chemical releases that could occur as a result of failures in process, procedures or equipment.” –Appendix C to §1910.119 (non-mandatory)

In the scenario we’ve been discussing I keep going back to the intent of the standard. When we brought this situation up for discussion it was because it’s one of those odd-ball situations where your gut instinct tends to lead you in the wrong direction. Upon reflection, I think there are many ways to address the issues that this situation poses. What follows is one way of dealing with the situation that I feel fits within a properly implemented Ammonia refrigeration PSM program that meets the modern understanding of what Process Safety Management entails.

First, the area in question is a refrigerated space with a small evaporator and its required piping and valving. If we were to build this today we’d likely place the unit in a penthouse or provide some alternative means of protection. Unfortunately, the vast majority of us deal with legacy systems that were designed with criteria that did not exactly place safety on the top of the list. We have to deal with the systems we have – not the ones we wish we have.

In this case the evaporator is against a wall behind some manually loaded racking. This is fairly common for ingredient rooms in Ice Cream plants and other such facilities. The air unit is well out of the way of where a worker can affect it and the rack itself actually provides a barrier to reaching the air unit with a manual pallet jack. Maintenance workers use a ladder to reach it for servicing. At some point in the facilities history a good deal of time, money and brain-power went into the PHA. The members of that PHA team analyzed the hazards of the process and the hazards around the process that could affect it. In the section of the PHA dealing with this room, there was a question about “Struck by” hazards. The team reasoned that there was never an intention of placing PIT (powered industrial trucks) in the space so the PHA did not consider it a credible hazard. But there were safeguards in place as well: There was a policy on forklift use and there were signs in place saying “No Forklifts.” More importantly there was no need to take a forklift in the area because due to space constraints it was easier to push a manual pallet jack in for the rare large load of flavorings that needed to go into the space.

I like to repeat the wise words of Trevor Kletz about 20 times each PSM class: “Institutions have no memory, only people have memories.” This is important because at some point people change, move on, get fired or promoted and eventually the only institutional knowledge of why forklifts weren’t allowed in the space, and why the situation was acceptable is enshrined in the Process Hazard Analysis or PHA.

To reiterate – the only memory of the hazards and safeguards in place is in a document that most people operating or maintaining the system will ever read, let alone become so familiar with that they can actively understand the hazards and safeguards present without referring to it: the PHA.

When the change of racking in the space was considered – or indeed any change takes place on or near a covered process – I like to ask the following question at the facility’s PSM meeting: To what extent can this change affect, or be affected by the process? While this differs from the usual practice of how most PSM implementers decide whether or not a MOC is required, I believe it is in keeping with the language of the standard:

1910.119(l)(1) – The employer shall establish and implement written procedures to manage changes (except for “replacements in kind”) to process chemicals, technology, equipment, and procedures; and, changes to facilities that affect a covered process.

It’s that last bit – “changes to facilities that affect a covered process” – that makes me want to perform a Management of Change. Perhaps your gut instinct tells you that the change (as it’s envisioned) would not affect the process. Surely, if the change in this case was carried out correctly I think we would all agree it would not have. I’ll quote from the OSHA compliance guidance given in CPL 03-00-004 (the Refinery PSM NEP):

A MOC procedure is a proactive management system tool used in part to determine if a change might result in safety and health impacts. OSHA’s MOC requirement is prospective. The standard requires that a MOC procedure be completed, regardless of whether any safety and health impacts will actually be realized by the change. The intent is, in part, to have the employer analyze any potential safety and health impacts of a change prior to its implementation. Even if the employer rightly concludes there would be no safety and health impacts related to a change, 1910.119(l)(1) still requires the employer to conduct the MOC procedure.

As part of my PSM team’s discussion we’d look at the PHA for the area in question. Were there any identified hazards and safeguards? There was no credible struck by hazard because there were no forklifts. Well, we’re about to change that right? Every safeguard we identified is also being thrown out the window. To my mind there is no doubt: This is a change, and the change can affect the safety of my process.

I’m not sure how your MOC procedures work in practice, but I know that this entire conversation that I’ve described above can take place in less than 15 minutes. I also know that the safeguards we decide upon will be fairly easy to design, implement and document. I wouldn’t think that the entire process would take over a half an hour.

In your article you discuss the threat of “drowning in paperwork of little or no value”, but a MOC isn’t paperwork. A MOC is an analysis of a change and it’s affect on the system that is documented on paper. We do safety a great disservice when we confuse the form with the function. If I may quote from GCAP’s training manual on the MOC element:

“No single form can work for every type of change to the system. While a form can be used as guidance on conducting a management of change, it is only meant to document the change – not to manage it. Managing a change is no less complex than managing a shop floor or a warehouse; you might be able to document that you did it on a form, but no form can tell you how to make the hundreds of decisions required of management on a daily basis.”

We are free to document that we managed the change in any way that meets the requirements of the standard. Every bit of the discussion in this article on the nature of the change and its impact would have occurred in a safe facility with a PSM program – all I am saying is that since we are already doing the work, we might as well document it as a MOC and take credit for the work!

You also mention in your article that there are other ways of dealing with this change. I agree completely – there are many ways to handle it safely. In my opinion though, there is only one compliant way to handle it in a PSM covered process on the small scale most Ammonia refrigeration systems operate on. Why use a different tool when we already have one designed to manage changes that we are already familiar implementing?