Ever get down because the operator that is always “fixing” a “broken” refrigeration system is viewed as a hero while the operator who reliably and efficiently operates a system is forgotten about? Read on and see what I think you can do to get back on your boss’s radar even when things are running smoothly!

“Don’t fix what isn’t broke” is a good maintenance motto for much of your refrigeration equipment but it is a lousy motto for processes. Sometimes a piece of machinery is just perfectly suited to the task you are asking it to do. Let’s use one of my favorite examples: the M1911 pistol:

The design is essentially unchanged since its introduction in 1911. That’s some awe-inspiring design! Firearm manufacture started in the 13th century and through constant improvement became what we now take to the pistol range. Imagine if those early inventors worked on their new machine and stopped the minute they got something that “got the job done” without trying to make it work better:

I’m not suggesting you start tinkering with your ammonia pumps and compressors; Modern refrigeration equipment is extremely complex and finely tuned. Chances are though, that you do have plenty of suboptimal processes using that equipment. For many end-users, if the cold area is cold then things are “working” and they want things left alone. The fact that they may be overstressing their equipment and wasting tens of thousands of dollars in extra electricity is not known or simply ignored.

Let’s say you are one of the great refrigeration operators out there: you’re professional, attentive, and knowledgeable. You adhere to your mechanical integrity schedule for preventative and predictive maintenance with an almost religious zeal. Because you do the right things your system operates with very little downtime. The result of all this work, if you are like the vast majority of great operators out there, is that you fall off your boss’s radar. They don’t think about you because they don’t have to worry about refrigeration working for them. Your success means you shrink into the shadows – never a good place to be if you are looking for a promotion or a pay raise!

Is there a way out of this situation without creating “opportunities” to come to the rescue? Yes, there is! You already operate your system in a standard manner that works well, but is there a way it could work better? What would better look like? Would lower electrical costs, reduced downtime and minimal wear & tear be better? If you could quantify those positive changes in dollars, wouldn’t that get you back on the radar at work?

You bet it would! Very few things speak to management louder than dollar bills!

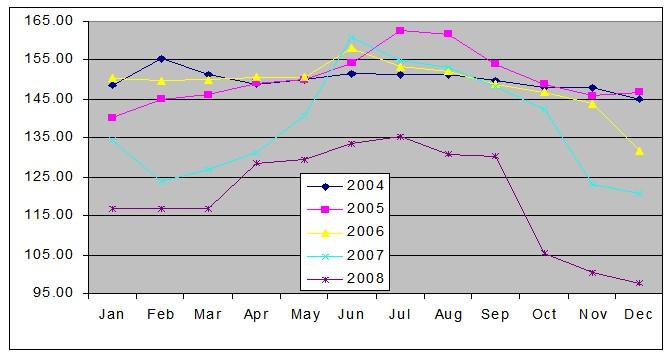

Average Head Pressure:

Electricity Usage:

Don’t settle for “good enough” when you have room for significant improvement. Excellence isn’t just a skill – it’s an attitude too. Optimize your defrost schedules, properly set your back-pressure regulators, balance your evaporators, de-scale you condensers, monitor your chemical concentrations to reduce usage, lower your head pressure. There are almost always things you can improve! Document your improvements and the savings from them and present them to your management. With any luck you can get the well-deserved positive attention you need for that long sought promotion and raise!

Brian, you’re absolutely correct. I was once in the very situation you describe here. when I first started working for this company we had a lot of equipment breakdown, it was a regular occurrence that I could count on dealing with every shift. being new to the industry of ammonia refrigeration though, it was actually a really great learning experience. Fast-Forward a couple years and we were running really really well, no downtime hardly at all. We were forgotten about. So I started to wonder, how can I bring some attention back to our department and show what a great job we were doing?

we happened to have an ultrasonic gun sitting on a shelf in my managers office so I began a 3 month air leak survey. I recorded the location of the leak, approximate size, and shape of the hole. I then would place a repair tag on the leaky air line. The repair tag numbers and locations were recorded on an excel spreadsheet which was then farmed out into repair work orders. Within a month all the air leaks in the plant were repaired and we were able to turn a compressor completely off. i figured up the KW usage savings and wrote up a quick report on the energy savings our department had accomplished. It came out to around $108,000 a year! I also found a really cool formula that lets you convert kw hours usage into pounds of CO2 emitted from the power plant so i was able to put a “Green” spin on it that my manager could take to his manager.