Yes, it really has come to this. Let’s start with a single citation…

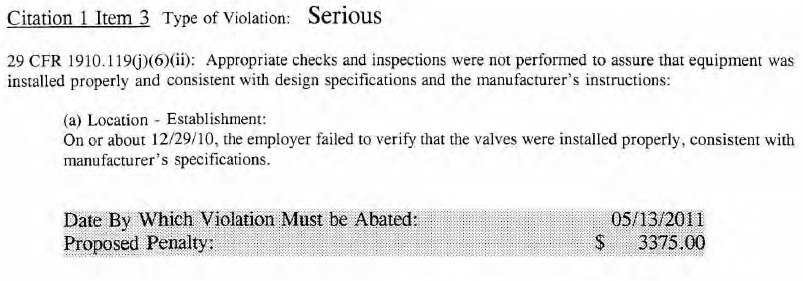

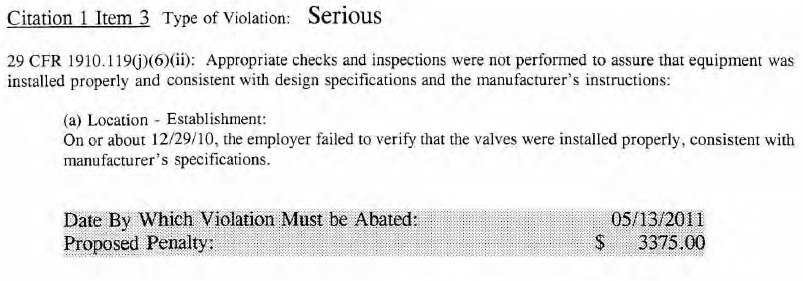

What equipment could this citation be concerning? Take a look at the compliance officer’s narrative:

What equipment could this citation be concerning? Take a look at the compliance officer’s narrative:

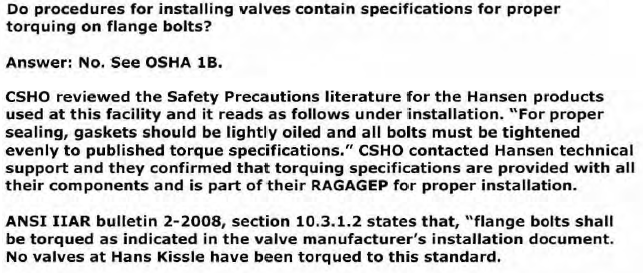

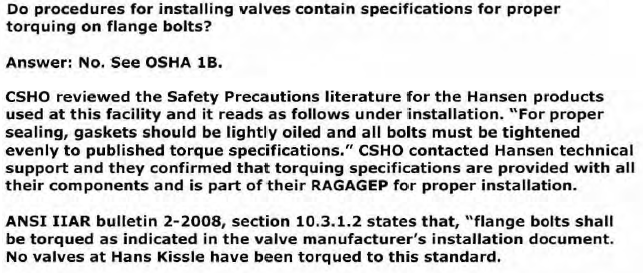

The officer went on to say in the OSHA 1-B Inspection worksheet:

All valves with flange bolts (Hansen/Parker Hanafin) used in the covered process need to be torqued with a torque wrench consistent with the manufacturer’s specification and their RAGAGEP. Although the FACILITY contracts out the Mechanical Integrity work to CONTRACTOR the FACILITY did not have the specific language in the contract or a way to ensure that valves are torqued properly. Improperly installed flange bolts that aren’t torques properly may result in a release of a highly hazardous chemical such as ammonia.

This may sound absurd to many with experience in the Ammonia industry, but don’t take this lightly: I am aware of at least four facilities that have been cited for not using torque wrenches for flanged valve installation. I am also aware of at least one repeat citation for $25,000! Once something like this has been established, you can expect to see it over and over again.

.

Both the RAGAGEP (IIAR) and the PSM/RMP regulations say we should install equipment in accordance with the manufacturer’s recommendations. When the manufacturer includes “published torque specifications”, we have no choice but to follow them.

.

.

I‘ll quote Hansen: “For proper sealing, gaskets should be lightly oiled and all bolts must be tightened evenly to published torque specifications”

About Brian Chapin

PSM / RMP Compliance Consultant

What equipment could this citation be concerning? Take a look at the compliance officer’s narrative:

What equipment could this citation be concerning? Take a look at the compliance officer’s narrative: